The Carbo Ejector Carbonate Removal System by American Chemical and Equipment

American Chemical and Equipment is very proud of the service they provide and of their high-quality products. One glowing example is their new Carbo Ejector Carbonate Removal System. This particular unit is an innovative system used for carbonate removal from plating baths. This quality equipment features a continuous “flow through” design with an elevated rate of the removal of carbonate. These exceptional products are designed specifically for the efficient and economic removal of excess carbonates and other type salts from plating baths.

With the Carbo Ejector Carbonate Removal Device, there are no more small batch treatments with an extended waiting period and lengthy processing time. Other outstanding features include:

- Efficient, high BTU output LOW TEMP refrigeration with an ultra- modern screw type compressor.

- The option of liquid or an air- cooled condenser unit.

- Precisely controlled treatment temperature with a wider range of low temperatures if needed.

- Low volume of plating bath (around 60 Gallon) contained in the treatment tank.

- Drum crystallization with ejection of portion of free-flowing carbonate slush about every one and a half minutes.

The Principle operation of the Carbo Ejector Carbonate Removal System is based on the premise of inducing the crystallization of accumulated unwanted salt. It is accomplished by lowering the solution temperature below the compound’s saturation point. This then drops out it’s excess carbonate (salt) from the solution to form a small crystalized slush.

Nearly all competitors use the “batch method” of crystallization, This is very limited and time consuming. It also requires significant attention and monitoring. The Carbo Ejector eliminates all this extra work and trouble. It is truly new technology and “state of the art”. Please call American Chemical at (708) 531-9199 with any question or for further information regarding the Carbo Ejector.

Amer Chem firm serves companies worldwide and provides equipment for many different industries including the military, electronics companies and the always evolving automotive line of business. American is continually working as meticulously as possible to improve the function, value and beauty of its many products. They take enormous pride in its high corrosion resistant processes. These include chemicals such as chromates, phosphates, aluminum, conversion coatings and other materials used for custom coatings. Additionally, they have products available for sale such as zinc, alloys and nickel to ensure optimal metal finishing results for all of its valued customers.

American Chemical is always at the very forefront in Carbonate Removal Systems and Devices and is on the cutting edge of new procedures and products for metal finishing processes and equipment. With headquarters in the Chicago suburb of Northlake, IL Amer Chem would be glad to hear from you with any questions or comments. Contact them today at (708) 531-9199 for more information.

Among the features that sets American Chemical apart is their philosophy in allowing accessibility and service in addition to equipment and chemicals. Do not be deceived – not all plating supply companies conduct business in this manner. Amer Chem is happy to offer Tanks, Liners, Control Equipment from pH and ORP to temperature.

American Chemical & Equipment has been a leader in the busy metal finishing industry since 1988. In fact, their company’s founder has been involved in the field for more than forty years. They are an extremely versatile and trusted firm with the very highest standards. Amer Chem creates high quality performance coatings for manufacturing, plating and painting to countries all over the world.

Innovative Carbonate Removal System for Plating Baths

- Continuous “ Flow Through” design with high rate of Carbonate removal.

- Design flow of 1+ Gal/Min.

- (actual flow of over 2 Gal/Min proved successful)

No more small batch treatments with long processing time.

- Efficient, high BTU output LOW TEMP refrigeration with modern screw type compressor.

- Option of liquid or air cooled condenser unit.

- Precisely controlled treatment temperature with wider range of low temperatures if required.

- Low volume of plating bath(~60 Gal) contained in the treatment tank.

- Drum crystallization method with ejection of portion of free flowing carbonate slush ~every 1.5 min.

Carbo eJector Features and Operating Principles

The Carbo eJector TM Carbonate Removal System is designed to efficiently and economically remove excess carbonates or other type salts from plating baths and various industrial process solutions.

The Principle operation of the Carbo eJector TM devices are based upon inducing crystallization of accumulated undesired salt. This is accomplished by lowering the solution temperature below the compound’s saturation point, which then drops out it’s excess carbonate (salt) from the solution to form a small crystalized slush.

Examples of Salts other than Sodium Carbonate are: Ferrous Chloride, Ferrous Sulfate, Aluminum Sulfate, Aluminum Hydroxide, etc. which are compounds with low solubility at lowered temperatures.

Typical industrial electrolytes and baths that the Carbo eJector TM can separate waste build up from include: Alkaline Zinc, Alkaline Zinc Nickel, Cyanide Zinc, Cyanide or Alkaline Copper, Anodizing Baths etc.

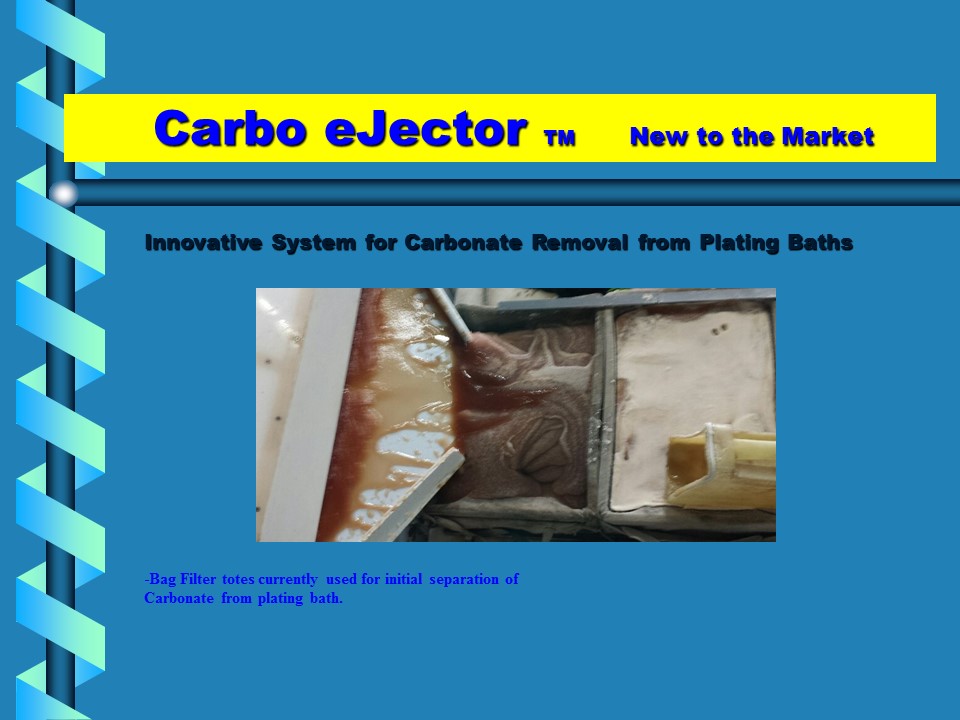

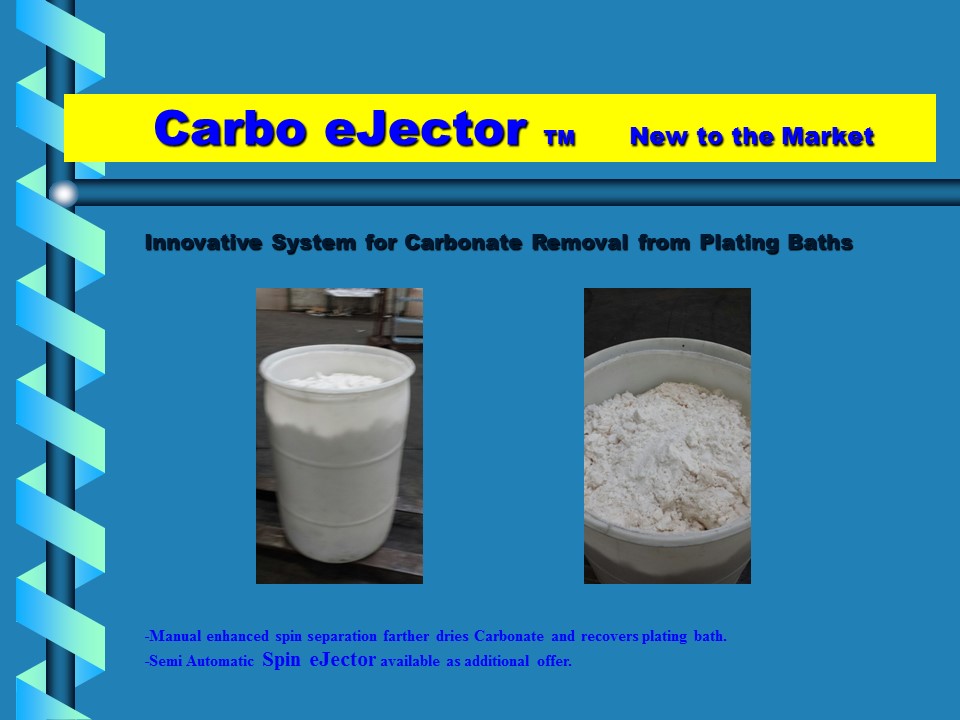

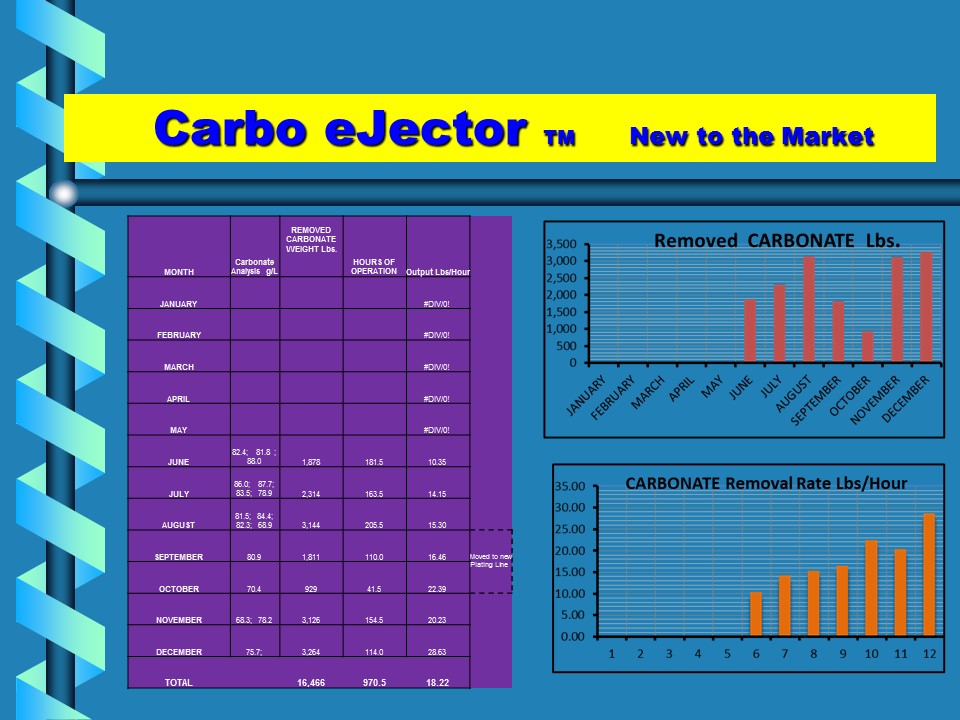

Carbo eJector TM Carbonate Removal Devices perform this treatment in an innovative manner by using a continuous *Flow Through Design at a rate of ~1 to 2 Gallons per minute of the cleaned bath through the Treatment Compartment. From here, formed Crystallized Slush contaminants are continuously and mechanically ejected from the plating solution in the Crystallization Compartment and in the next step, separated from the liquid by several possible methods with varied efficiency. 1.0) The simplest method being gravity filtration accomplished by the furnished filter bag totes. 2.0) The best possible separation being achieved by quick centrifugation or spin drying, with the possibility of returning the now cleaned solution back to the process tank potentially saving significant money and resources.

Please ask about those additional options if the volume of removed contaminant would offset the cost of treated bath or if the environmental requirements or concerns warrants such additional step.

- *Most competitors use the “batch method” of crystallization which is limited, time consuming and requires significant attention and monitoring compared to the Flow Thru design of the Carbo eJector TM.

MADE IN USA, easy access to spare parts